Chemical Vapor Deposition Coatings

Chemical vapor deposition (CVD) coatings from Ti-Coating, Inc. provide significant production increases and cost savings on a variety of metal cutting and metal forming applications. Since the introduction of CVD coating technology to the carbide cutting tool industry over 40 years ago, Ti-Coating remains committed to developing and refining this technology in order to broaden the range of applications.

Chemical vapor deposition (CVD) coatings from Ti-Coating, Inc. provide significant production increases and cost savings on a variety of metal cutting and metal forming applications. Since the introduction of CVD coating technology to the carbide cutting tool industry over 40 years ago, Ti-Coating remains committed to developing and refining this technology in order to broaden the range of applications.

In addition to constantly improving upon current technology, we work with our clients to identify the most effective and money-saving methods for addressing their CVD issues. Ti-Coating CVD coatings are the ideal choice for many difficult metal forming and metal cutting applications. Let us show you how we can not only deliver the best result, but also help you identify solutions for any chemical vapor deposition (CVD) coating problems you may encounter, like we do for many clients.

Due to the elevated temperature of the chemical vapor deposition process, care must be exercised with regard to material choice. But don’t worry, we’re here to help. Please contact Ti-Coating, Inc. for additional technical assistance.

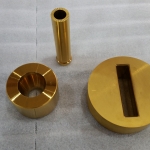

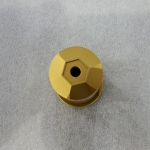

CVD Extrusion Dies

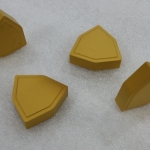

CVD Form Tools

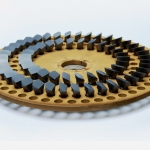

CVD Bar Pealing Tools

CVD Tube Scarfing Tools

Ti-Coatings’ Value Added Services

We provide our clients with exceptional value by delivering state-of-the-art services and systems, and through continued development of products and technologies. Ti-Coating is more than just our superior coatings, cleaning, and equipment; we also offer products and services that represent value-added benefits for you.